Is a professional enterprise that combines R&D, production, sales, and service for Central Air-conditioning equipment and systems. TECKA was founded in 1970, with rapid development in the past. For 50 years, TECKA has been the leading technology provider and system integration service provider in the field of conventional and integrated central air conditioner products.

- 2 Production factories (250,000 m2)

- 8 nationally authorized laboratories and testing centers.

- 650 staff, 120 technicians (30 senior title engineers).

- More than 100 patents.

- Participated in the compilation of more than 20 National Standards since 2006

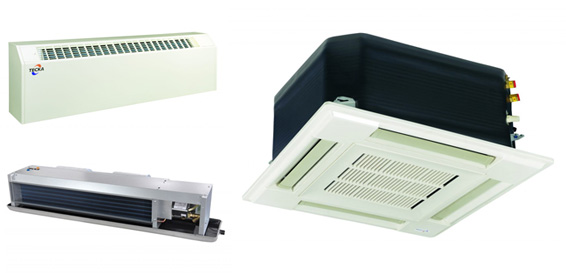

FCU

01

A cold-rolled silicon steel motor with a heat resistance feature translates to higher energy efficiency.

02

To ensure safety, the motors have high-quality capacitors and coil overheating protection devices.

03

The motor adopts oil-containing closed bearings with no refueling, significantly reducing the maintenance work.

04

Hydrophilic membrane heat elongated design is easy to drain, corrosion resistant, challenging to deposit ash, and the efficiency is high.

05

The unit adopts the extended air cooler design, combined with the “central symmetrical air outlet” technology, to avoid local eddy currents, the heat exchange is more adequate, and the operation is quieter.

06

Elongated water tray wrapped with heat-pressed PE insulation cotton to prevent the secondary condensation effectively.

07

The unit coil unit and the water tray are internally connected at the bottom of the “Ω” type instead of being installed on the side to avoid the condensed water polluting the ceiling by the cold screw bridge during side installation.

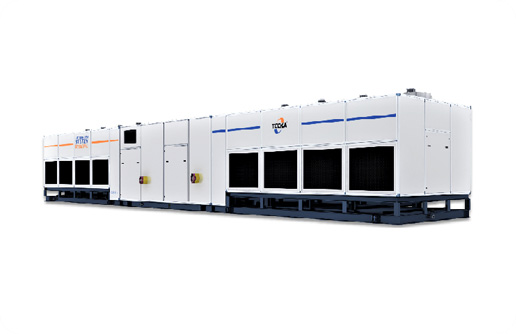

Dual Cooling

The intensive design of the TECKA energy station adopts an anti-corrosion and noise reduction canopy, with no need for a dedicated chiller room. The unit can be placed on the ground or rooftop flexibly.

TECKA intelligent energy station adopts the self-developed smart control system, which is always in the most efficient and energy-saving operation state. Compared with the traditional water-cooled chiller room, the COP is increased by 20%, and the operating energy consumption is saved by 30-50%.

Chiller

Large size touch screen operation panel adopted, friendly man-machine dialogue interface, easy to operate, data query and fault diagnosis.

Adopt the “zero mal-function” protection design concept, up to 16 measures for system protection, and protect them step by step according to the safety level of people, buildings, and equipment.

Separate the strong and weak electricity to reduce the interference of reliable electricity to the weak electrical signal. No other metal electrostatic protection board is needed to protect the unit. Make the team work more stable, and control accuracy is higher.

The compressor adopts zero-gap aviation-grade bearings, patented “α” type “a” ance drum technology, and a double-layer shell design, with low vibration and noise of the unit.